PharmaDoer® PTFE-HT Series Sterilizing Grade PTFE Pleated Filter Cartridges for air & gases. Increased temperature tolerance

PharmaDoer PTFE-HT series polytetrafluoroethylene (PTFE) pleated filter cartridges provide effective removal of microbes and submicronic particulate. Using inherently hydrophobic PTFE membrane, the PharmaDoer-PTFE-HT series has been designed specifically for feed air and venting in fermentation processes to prevent system contamination. Oxidation-resistent polypropylene hardware and polyester media support provides an extended operating temperature range.

Delivers fully retentive performance of aerosolized bacteriophage. Also is ideal for filtration of bulk gases and compressed air. Cartridges receive an ultra-pure water rinse to attain a low degree of extractable substances.

Features

- Inherently hydrophobic PTFE membrane.

- Superior grade PTFE membrane offers the highest degree of consistent performance.

- Superior chemical compatibility.

- UPW rinse assures cleanliness and low extractables. Validation guide available upon request.

Applications

- Fermentation process air & venting

- Bulk air & gas filtration

- Industrial process venting

Quality

- Each filter element is integrity tested by diffusion flow.

- Individual elements are tracked by serial number.

- Produced in a Class 10,000 clean-room environment for product purity & cleanliness.

- Manufactured within an ISO 9001:2015 certified quality management system.

- Certificate of Quality document is provided with each production lot.

Materials of Construction

| Media | PTFE |

| Support Layers | Polyester |

| Cage/Core/End Caps | Oxidation-resistent polypropylene |

| Seal Options | Silicone, NBR, EPDM, FKM, E-FKM |

Dimensions

| Diameter | 69mm (2.72") |

| Lengths | 10”, 20”, 30”, 40” |

Operating Conditions

| Operating Temperature | 100°C (212°F) max. |

| Operating dP (max.) | 4 bar (58 psi) @ 20°C (68°F) 2 bar (29 psi) @ 80°C (176°F) |

| Change-Out dP | 2.6 bar (38 psi) @ 20°C (68°F) |

Integrity Test Parameters

| Diffusion Flow | <20ml/min @ 1.035mbar; 60% IPA solution |

| Water Intrusion | <0.75ml/min @ 2,500mbar |

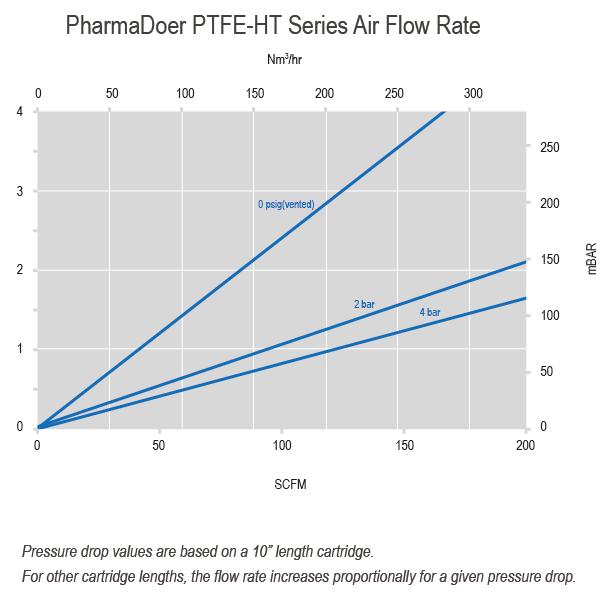

Clean Pressure Drop

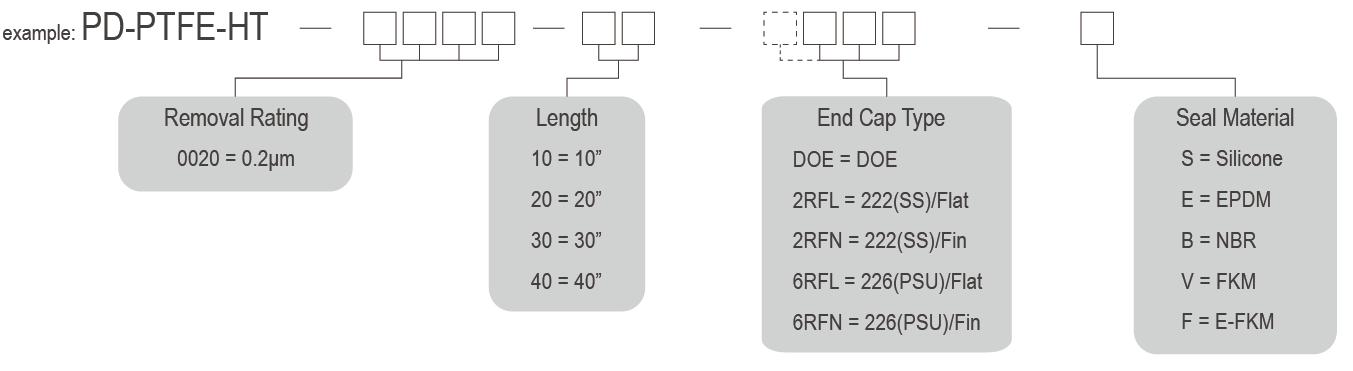

Ordering Information